Maximator Nitrogen Generators

Save storage space and money by generating your own supply of Nitrogen. Cut out the need to order from elsewhere, and forget about those refilling and delivery charges! Generate Nitrogen to the exact amount and purity that your application needs.

Nitrogen Generators use a workshop air supply to generate high purity nitrogen, which can then be utilised as it is at around 5 Bar (72psi) or coupled with one of our compressor systems to generate an in-house high pressure nitrogen supply. Nitrogen generators are normally supplied with an air dryer to condition the air prior to it being passed through the system to generate nitrogen. This protects the generator media.

These nitrogen generators ensure a cost-effective, reliable and safe supply of nitrogen.

Maximator use only German sourced Carbon Molecular Sieves (CMS) and all units are assembled and tested in our factory in Cheshire.

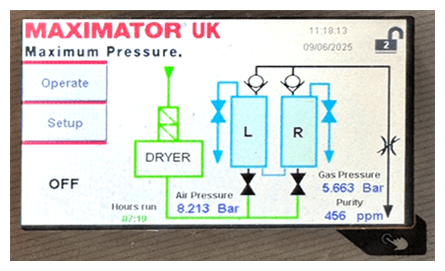

This image from a high-purity G750 generator shows the controller with a colour touch screen which provides visualisation of the status and setup of the unit.

This image shows the screen where the PPM is at 456 which demonstrates we have a generator that is able to achieve purities of 99.95%. This purity level is suitable for applications like chemical blanketing, food processing, and some industrial processes that require nitrogen to displace oxygen.

Nitrogen purity is shown on the screen as standard. Alarms for Air Pressure and Nitrogen purity can be set, and the operating pressure can be managed from the screen.

In this configuration, we include air filtration and a dryer to protect the CMS.

Nitrogen Generators G200/G300/G450/G600/G750/G900

These nitrogen generators ensure a cost-effective, reliable and safe supply of nitrogen.

They work according to the principle of pressure swing adsorption, in which oxygen molecules are deposited on carbon molecular sieves,

generating nitrogen of the desired purity. The molecular sieve is regenerated by purging with a portion of the generated gas.

- High quality N2 gas for industrial applications

- Pressure swing adsorption process

- High quality air separation media

- Cost Effective

- Reliable & Safe supply of Nitrogen

- Up to 99.95% N2 – Purity

Options available for nitrogen generators include:

A range of generators capable of generating up to 72 m3/hr at purities up to 99.95%

High purity versions delivering purity up to 99.99%

Systems with integrated boosters for 27 Bar (400 psi)

Systems with integrated compressors for 350 Bar (5000 psi)

Systems for high pressure up to 2400 Bar (34,500 psi)

Accessories include inline Oxygen level monitoring.

Maximator UK Nitrogen Generator Column Outputs

| On Mobile Devices Scroll >>> | |||||||||||

| Flow Based Upon % Purity Of Nitrogen Gas | |||||||||||

| Model | Column Size | No of Column Pairs | Flow | 95% | 96% | 97% | 98% | 99% | 99.5% | 99.9% | 99.95% |

| G200 | 1000 | 2 | m3/h | 16 | 14.6 | 14.2 | 12 | 10.2 | 8.4 | 5.8 | 5.2 |

| lpm | 267 | 243 | 237 | 200 | 170 | 140 | 97 | 87 | |||

| G300 | 1000 | 3 | m3/h | 24 | 21.9 | 21.3 | 18 | 15.3 | 12.6 | 8.7 | 7.8 |

| lpm | 400 | 365 | 355 | 300 | 255 | 210 | 145 | 130 | |||

| G450 | 1400 | 3 | m3/h | 36.3 | 33 | 32.1 | 27.3 | 23.1 | 18.9 | 13.2 | 11.7 |

| lpm | 605 | 550 | 535 | 455 | 385 | 315 | 220 | 195 | |||

| G600 | 1400 | 4 | m3/h | 48.4 | 44 | 42.8 | 36.4 | 30.8 | 25.2 | 17.6 | 15.6 |

| lpm | 807 | 733 | 713 | 607 | 513 | 420 | 293 | 260 | |||

| G750 | 1400 | 4 | m3/h | 60.5 | 55 | 53.5 | 45.5 | 38.5 | 31.5 | 22 | 19.5 |

| lpm | 1008 | 917 | 892 | 758 | 642 | 525 | 367 | 325 | |||

| G900 | 1400 | 6 | m3/h | 72.6 | 66 | 64.2 | 54.6 | 46.2 | 37.8 | 26.4 | 23.4 |

| lpm | 1210 | 1100 | 1070 | 910 | 770 | 630 | 440 | 390 | |||

High Pressure N2 Generator Systems

VP250/350G High Pressure Gas Generator

Capable of delivering up to 18 Nm3/hr (250 lpm) of Nitrogen at purities of up to 99.5% against pressure of up to 350 Bar.

Generator

• Includes refrigerant dryer and air filter

• Carbon molecular sieve for long and efficient service and stable purity

Compressor

• Output flowrate 10 or 30 Sm 3 /hr (6 or 17.6 SCFM)

• Maximum working pressure 350 Bar, 5075 psi

• Operating speed 1400 rpm max

• Three stages of compression

• Industrial design for continuous operation

• One stage per cylinder – no double acting cylinders, for effective heat dissipation and reliable operation

• Pressure lubrication by oil pump to big end bearings

• Oversized cooling fan

• Intercoolers, pressure gauge and relief valve at each stage

• Extended 2000 hr service interval

• High efficiency microfilter

• Low oil carryover

• Belt drive with automatic tensioning

VP160/30G

Capable of delivering up to 10 Nm3/hr (160 Nlpm) of Nitrogen at purities of up to 99/5% against pressure of up to 30 Bar.

If you are interested in a quotation for one of our High Pressure N2 Generator Systems, please click on the button below, or get in contact with our office

Tel 01606 636000 or email sales@maximator.co.uk