Maximator UK Accelerates Hydrogen Learning

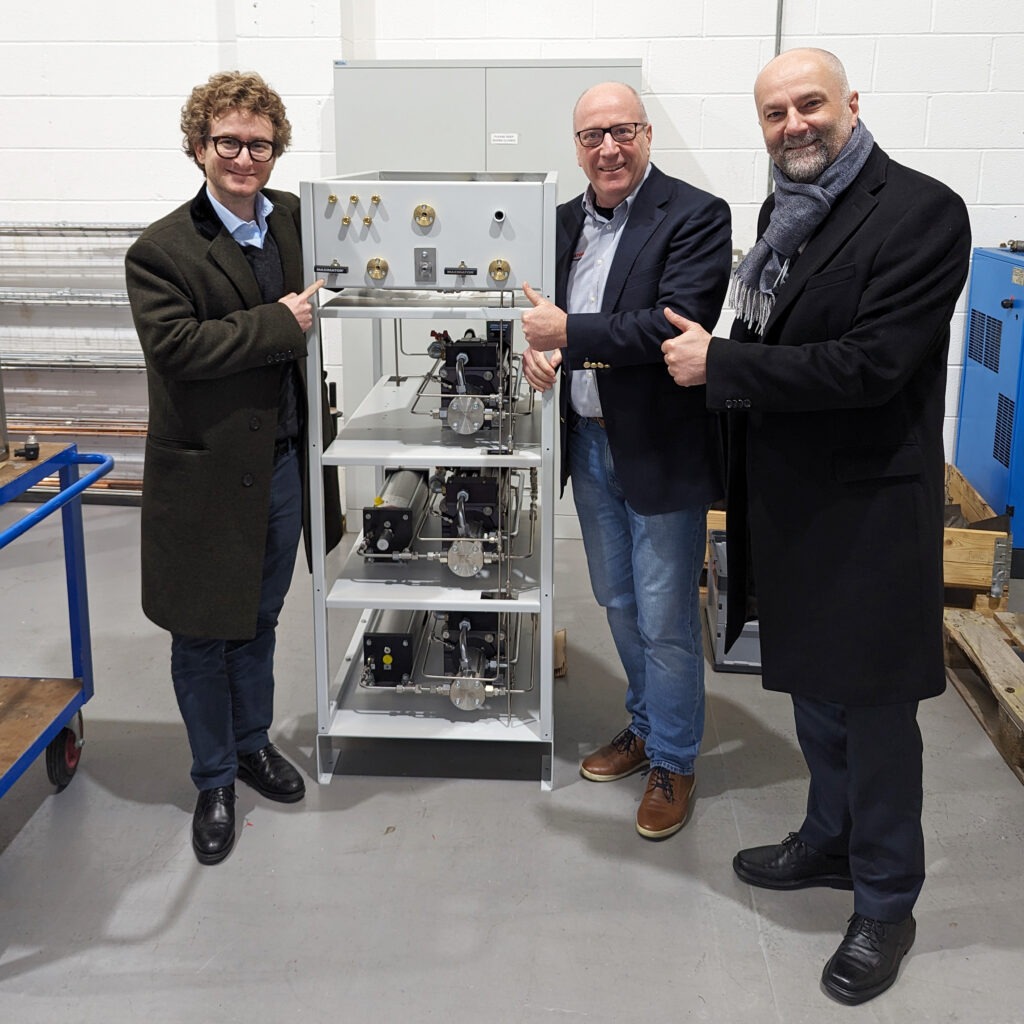

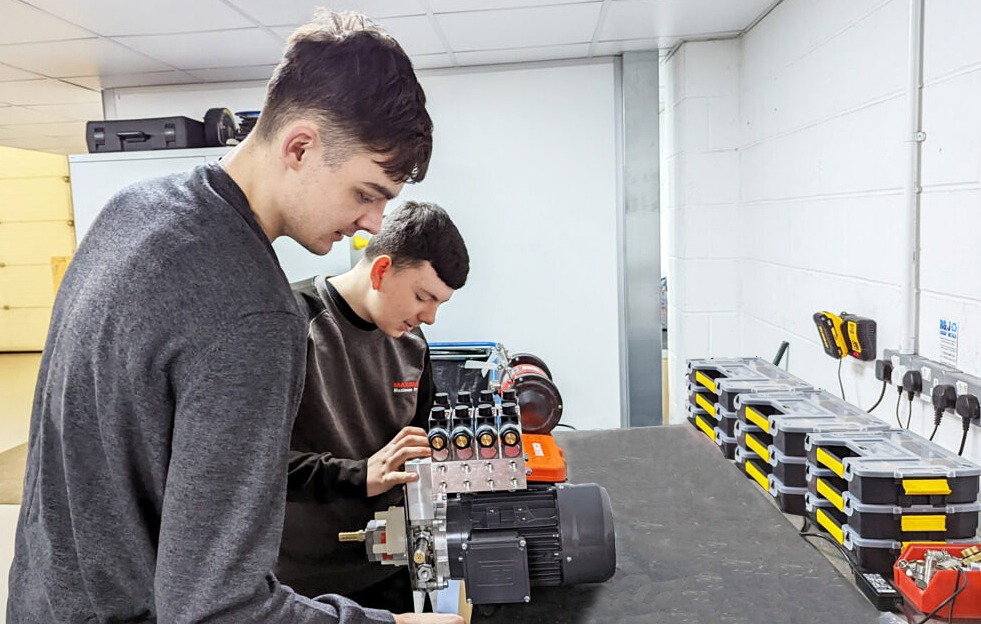

Within the space of 3 years, Hydrogen has become a key business area for Maximator UK. This brings many technical challenges, to which the Maximator UK team has risen. The entire team has been on a learning curve in this rapidly growing technical space.

Luckily, we are part of the Global Maximator family and have access to the best technical learning resources from the market leader in high pressure Hydrogen. At the same time, UK based training in practical aspects ensures that the team has the knowledge and skills required.

Maximator UK – your partner for High pressure Hydrogen