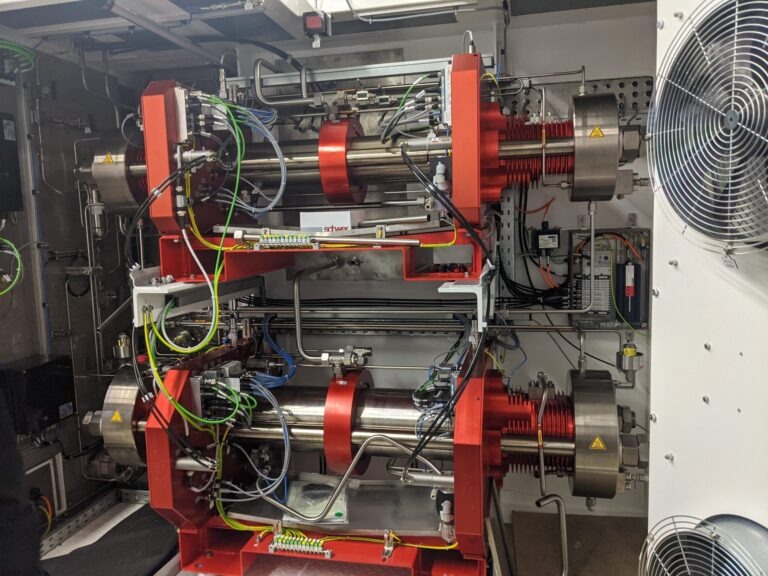

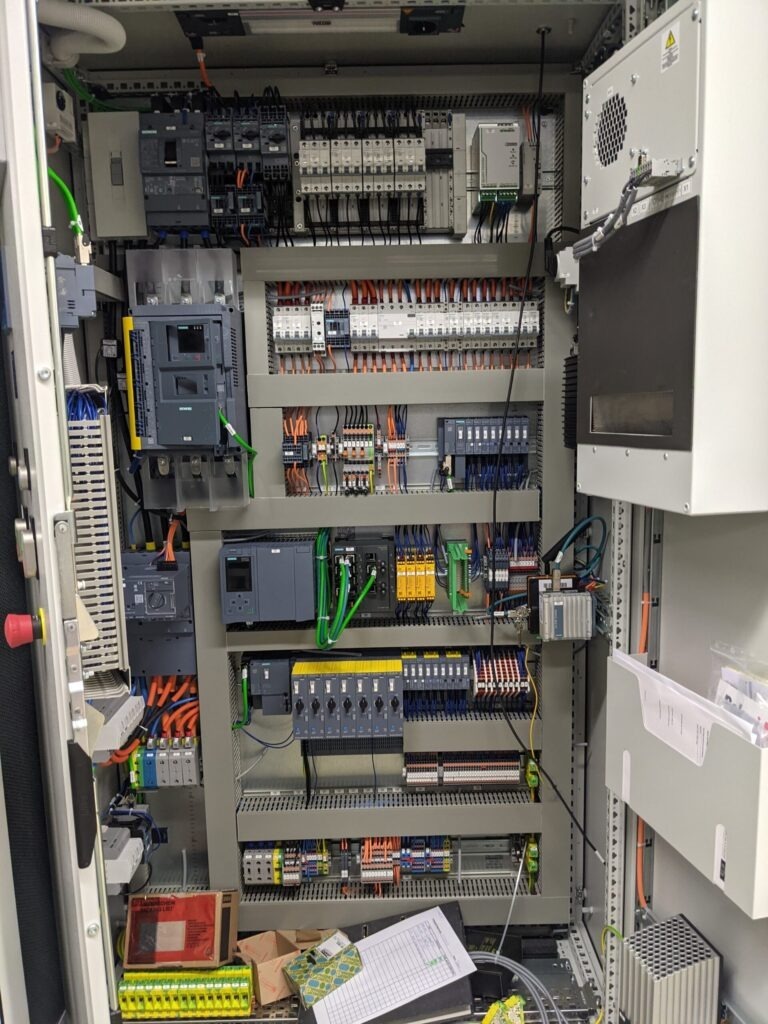

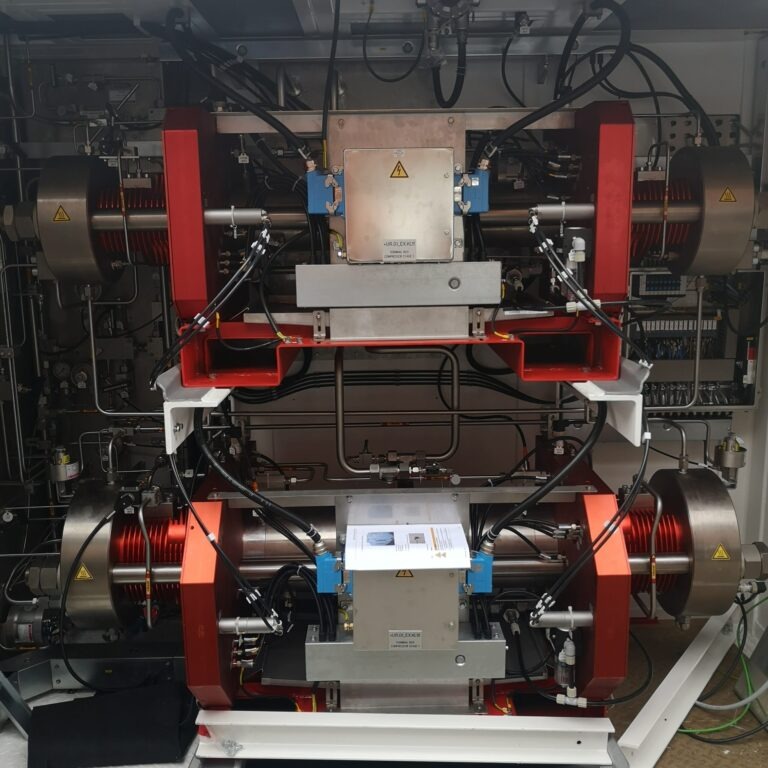

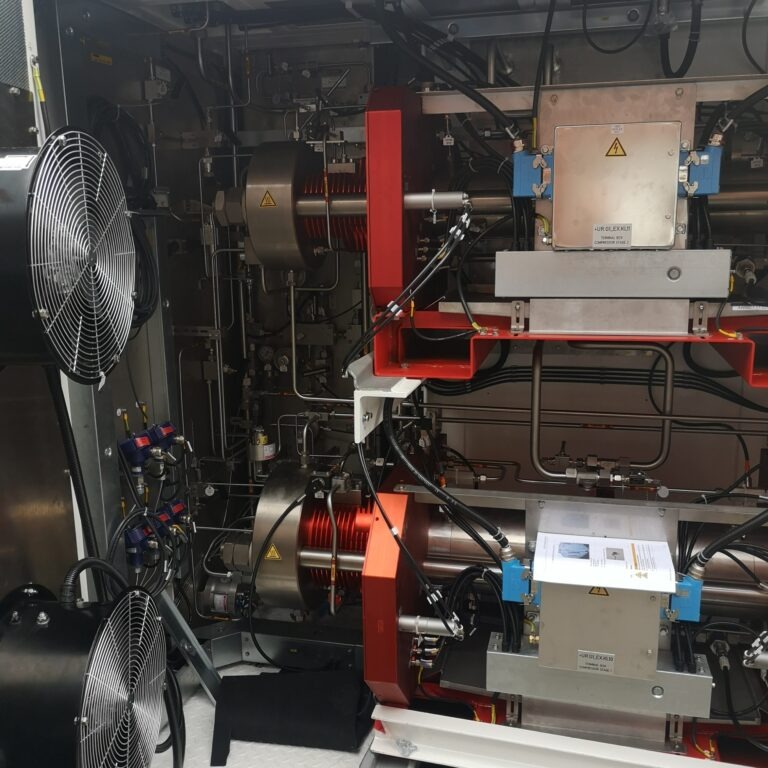

Hydrogen as the new and clean energy carrier of the future is becoming increasingly important. Especially technical solutions for compression and storage, but also for testing and for the qualification of products with high pressure.

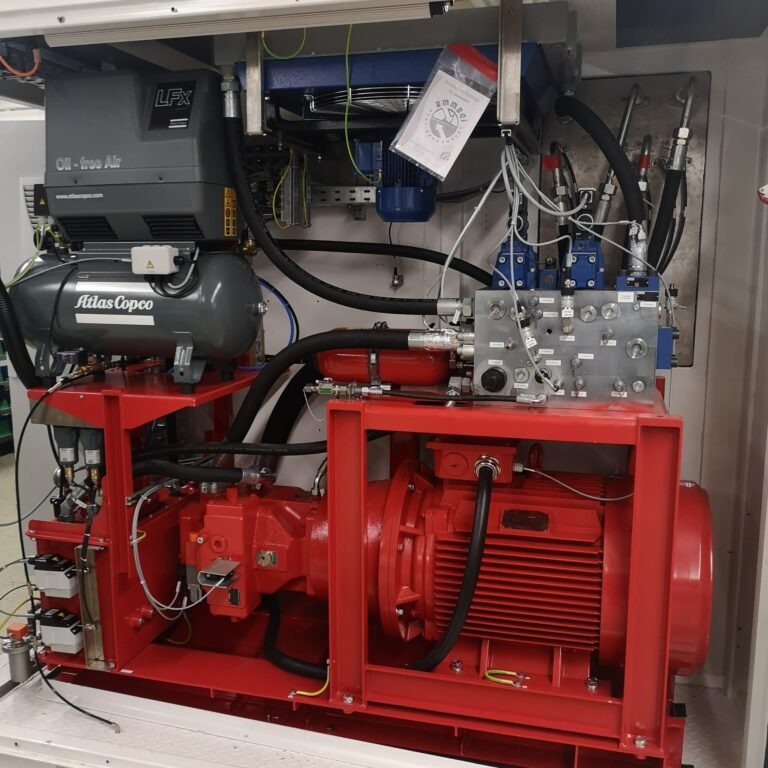

As a specialist for compression of gases, our products have been successfully used for hydrogen applications for decades. With our new special brochure, we are presenting all products from our Components division that are particularly suitable for hydrogen service in one catalog for the first time.

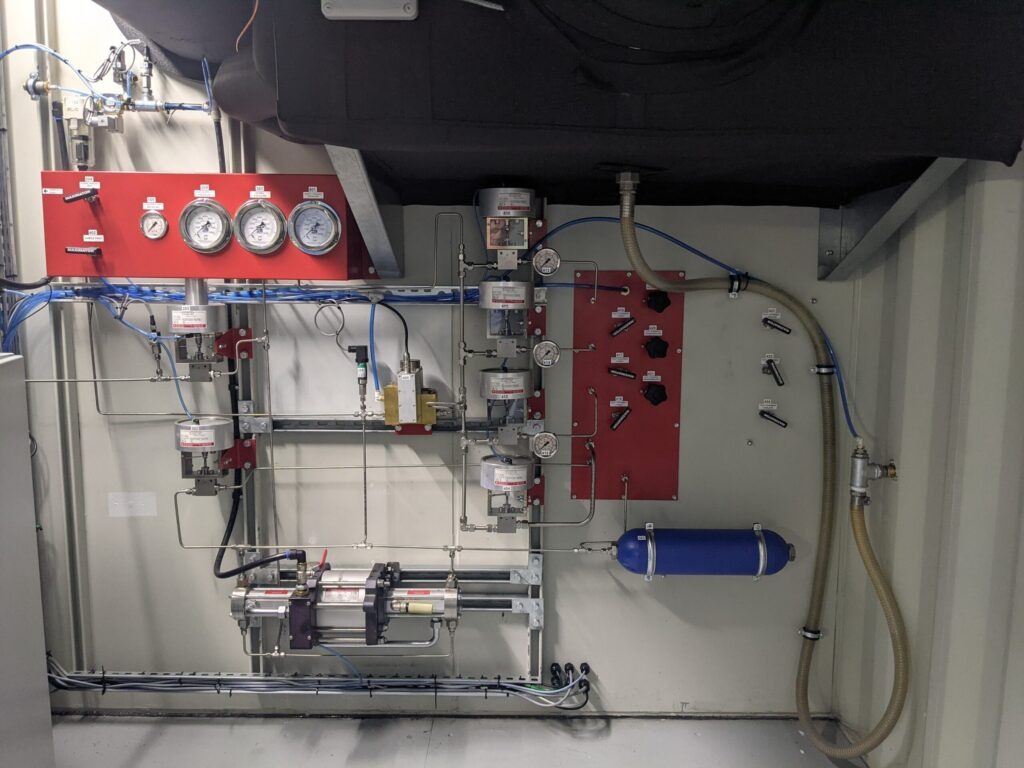

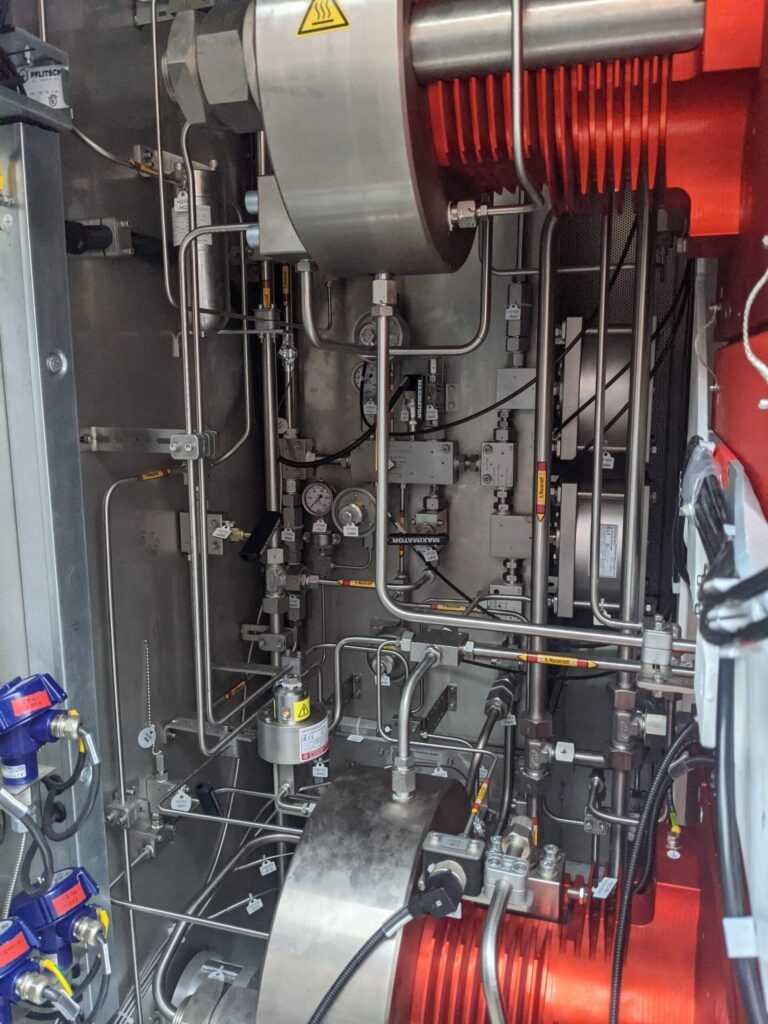

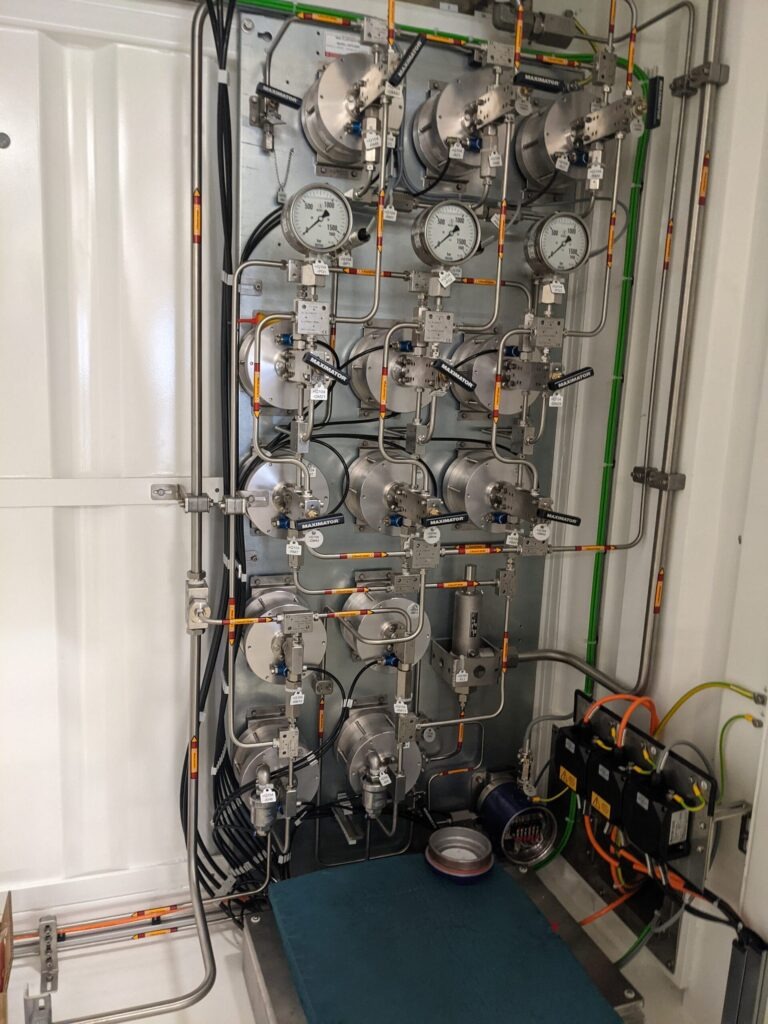

In addition to the gas compressors of the DLE series, valves, fittings and tubing of the Medium Pressure series, we also present our newly developed, air operated hydrogen valves in detail. Another highlight are our new fittings with variable connections – this allows users to reduce the required number of components and connection points.

The catalog is available for download here:

Download Catalog Components for hydrogen service