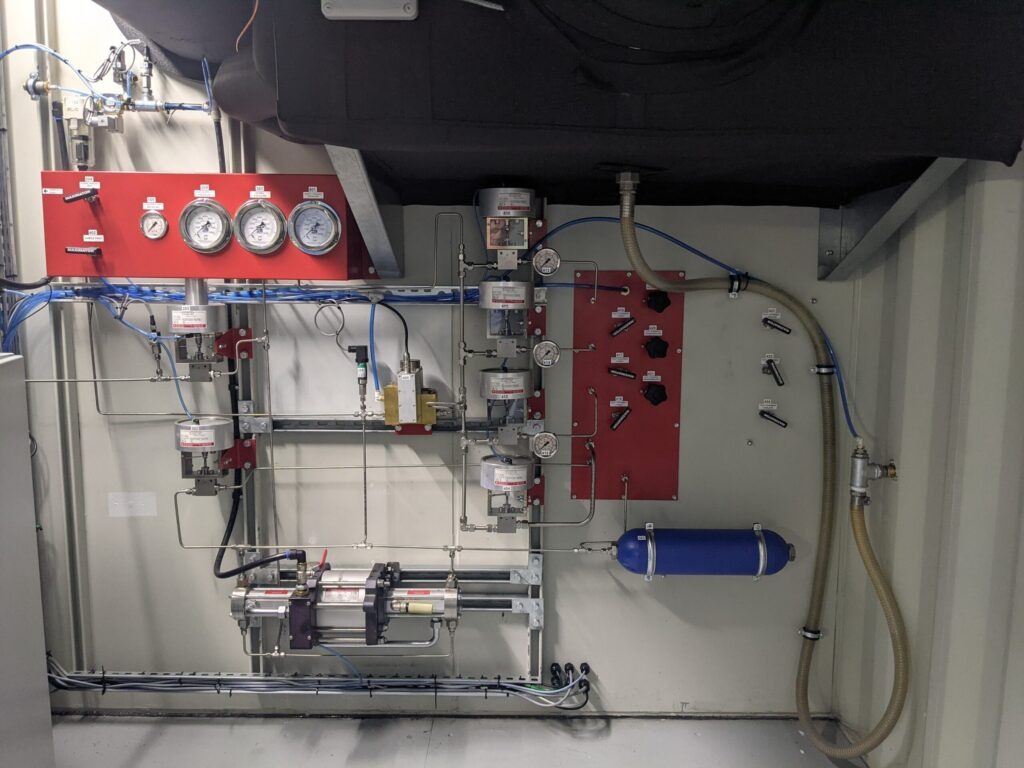

A Quick Boost For Pressure Testing

These four new compact gas booster stations are headed out to a large customer for marine pressure testing applications.

Rugged and simple to use, they are good for gas testing up to 600 Bar.

Contact us for all testing needs, whether gas, fluid, simple or automated.

#highpressure #maximator #gasbooster #marine #marinepressuretest