Hydrogen Products

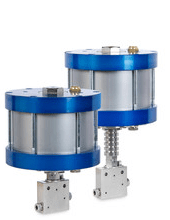

Maximator’s Hydrogen Division develops products specifically for Hydrogen, including refuelling solutions, valves, fittings and tubing, gas boosters and test equipment. We also have a range of services for testing of components for use in hydrogen service, including static and impulse pressure test, and autofrettage

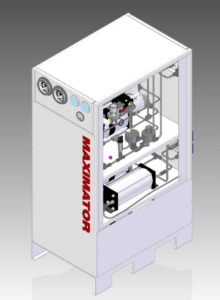

The Maximator MaxH2 Series is a Gas Compression System, specifically designed for Hydrogen compression up to 1000 bar, with scalable volume flow

Maximator has extensive testing capabilities, from simple hydrotest and pressure calibration to advanced pressure cycling and even burst testing. Services are carried out at Maximator’s UK factory in Winsford, Cheshire, and at its dedicated test facility in Nordhausen, Germany, with 700 square metres of indoor and outdoor space and testing equipment.