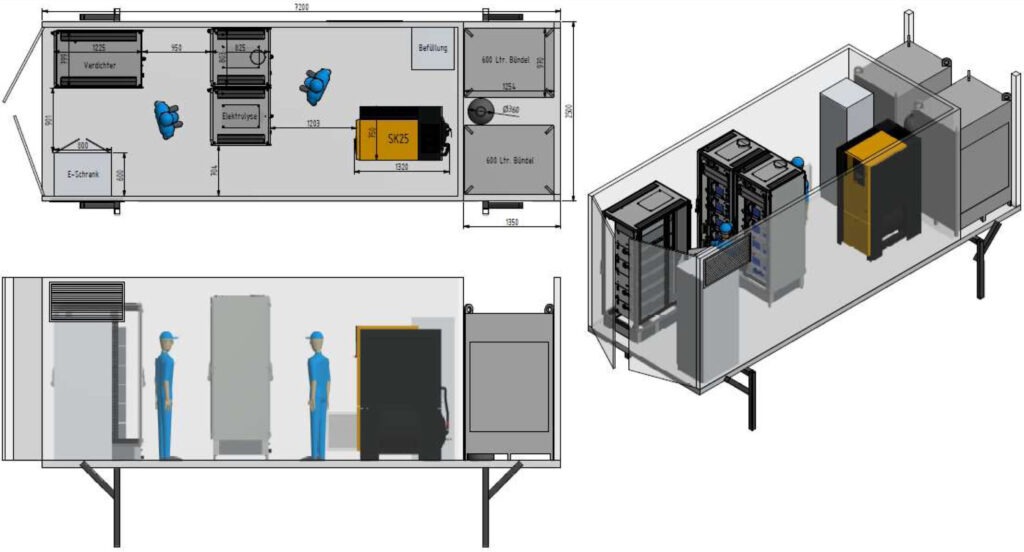

Modular Hydrogen Compression Systems

HULC - Hydrogen Unique Linear Compressor

HULC – THE MODULAR HYDROGEN COMPRESSOR UP TO 1,050 BAR

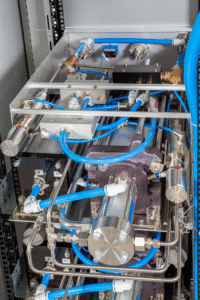

The Maximator HULC series is a modular gas compression system, specifically designed for hydrogen compression up to 1,050 bar with scaleable volume flow. In addition to innovative technologies such as the new Nitrogen Flow Purge purging process or our Flex Drive efficiency booster, the HULC series is particularly impressive due to its modularity in a wide range of hydrogen compression applications.

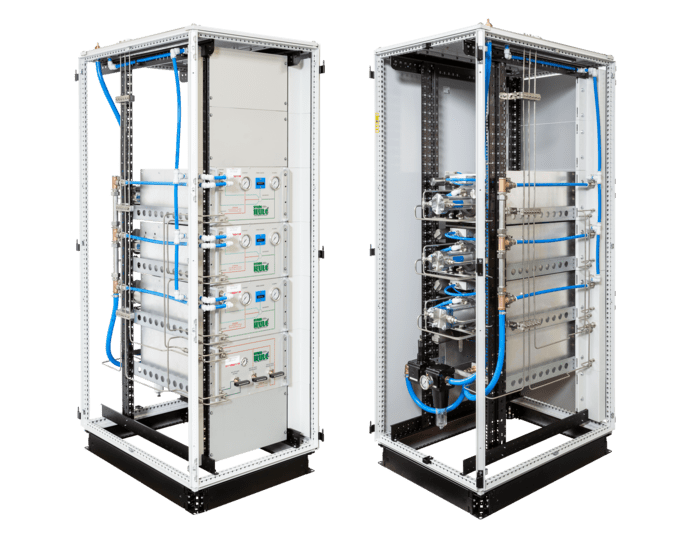

A standard configuration up to 1,050 bar consists of one control module (MASTER-module) and up to four gas booster modules (X-modules) – first stage module up to 90 bar, second stage module up to 300 bar, the third stage module up to 600 bar and the final stage module up to 1,050 bar. This configuration will provide a gas outlet flow of 2,5 kg Hydrogen per hour (average). For higher outlet capacities more modules can be connected easily.

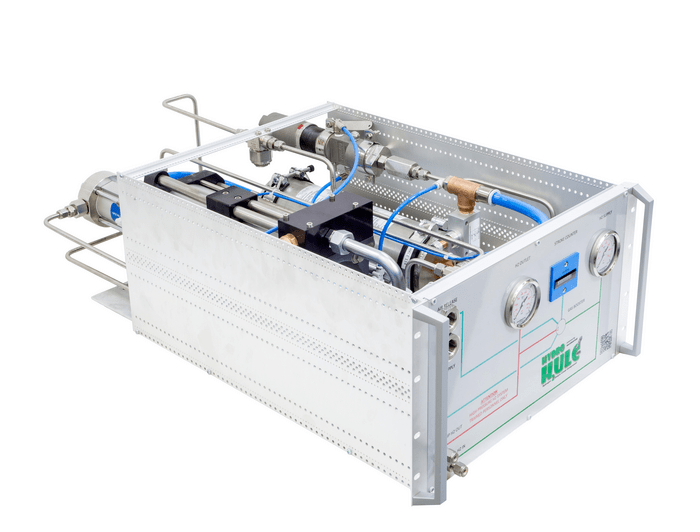

This complete series is installed in 19“ rack frame with front panel mounting and front connection for easy installation, exchange and access. This system can be easy installed and combined.

For all applications the MASTER module is mandatory and handles safety and functional features for a maximum of four X-modules. The X-modules can be combined and connected depending on the application.

- 1 master module can control up to 4 compressor modules

- Similar modules can be connected in series to achieve the highest pressures or in parallel to achieve the highest flow rates

- The complete solution is set up in 19“ racks in different heights (S and L)

- The maximum pressure level is 1,050 bar and up to a maximum of 2.5 kg of hydrogen per hour can be compressed (at 300 bar inlet pressure and 1,050 bar outlet pressure) as well as the parallel operation of two modules

- The minimum inlet pressure is 5 bar, the maximum inlet pressure is 300 bar (this means that the system can be used with almost any PEM/AEM electrolyser and also bundle accumulators up to 300 bar).

- All hydrogen-carrying high-pressure lines are equipped with our proven cone and thread fittings.

- High-pressure gas filter in each stage (7μm) for maximum purity

- Integrated cooling for maximum efficiency (no additional energy required)

- The system has no electrical connection (power supply), it is a purely mechanical system

- Each module is equipped with a stroke counter for easy lifetime monitoring

- Complete machine according to ATEX Zone 2 and Machinery Directive

Areas of application for the HULC

- Filling long-term storage tanks (Home Power Solutions)

- Hydrogen compression for forklift trucks and pilot vehicles such as buses and cars

- Laboratory applications that require the highest pressures and cost-effective solutions

- Hydrogen supply for drones

- Various power-to-gas applications

- Hydrogen compression for the supply of project sites that are difficult to access / autonomous energy supply

- Pressurisation for tests with e.g. forming gas (95% nitrogen and 5% hydrogen)

HULC – hydrogen compression taken to the next level

- Poka Yoke design of the modules (confusion-free design)

- Nitrogen purge: NFP Nitrogen Flow Purge for maximum safety

- CE labelling according to ATEX (ATEX Zone 2 possible)

- CE according to Machinery Directive

- Fail safe (less manual intervention possible)

- Higher degree of automation

- Purge function on the high-pressure side: inertisation of the high-pressure sections with nitrogen

- Simplified maintenance processes thanks to user-friendly design

- Pneumatically operated emergency stop

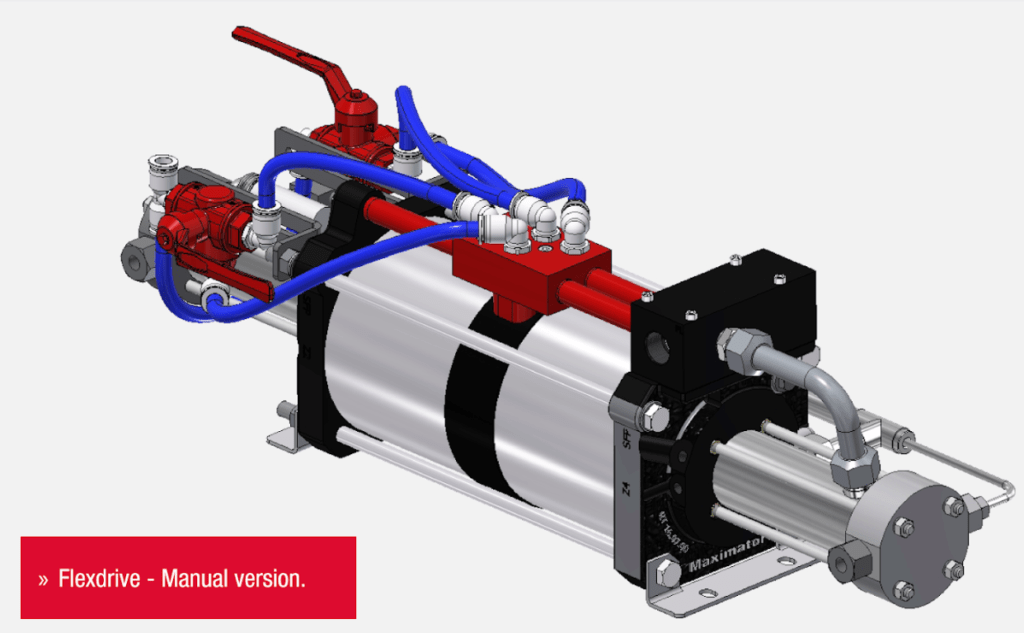

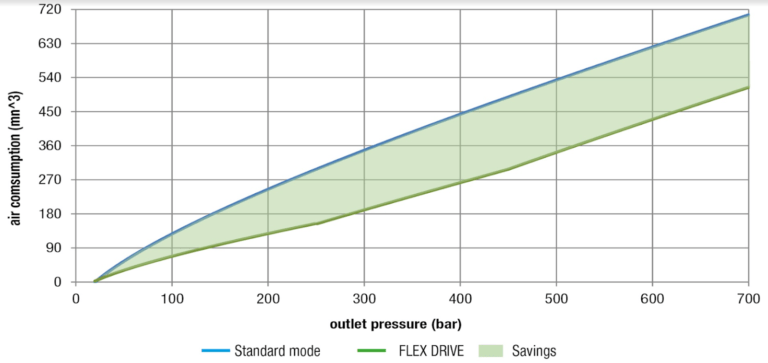

The efficiency of the gas booster will be improved by the patent-proven “FLEXDRIVE” modification.

Flex Drive

With Flex Drive technology, we offer our customers a unique opportunity to get the most out of their high-pressure technology in terms of efficiency. The technology allows the two air drive parts to be pressurized independently of each other and therefore only one of the two compressed air drives to be used when the power requirement is low (principle of the area ratio drive section vs. high-pressure section).

This is particularly advantageous when filling large storage tanks over long periods of time or in the process of initially low-pressure relevant volume flows. When a certain pressure level (Flex pressure) is reached and one air drive section is no longer sufficient to supply a constant volume flow or pressure, the second air drive automatically switches on.

- Patented FlexDrive technology: Save up to 40% compressed air (BAFA eligible)

- Optionally available for all Hulc modules

- Time savings of up to 20% can be achieved in applications for filling storage tanks

Enquiries

If you are interested in a quotation for one of our HULC Systems and/or HULC Flexdrive, please click on the button below, or get in contact with our sales team

Tel 01606 636000 or email sales@maximator.co.uk