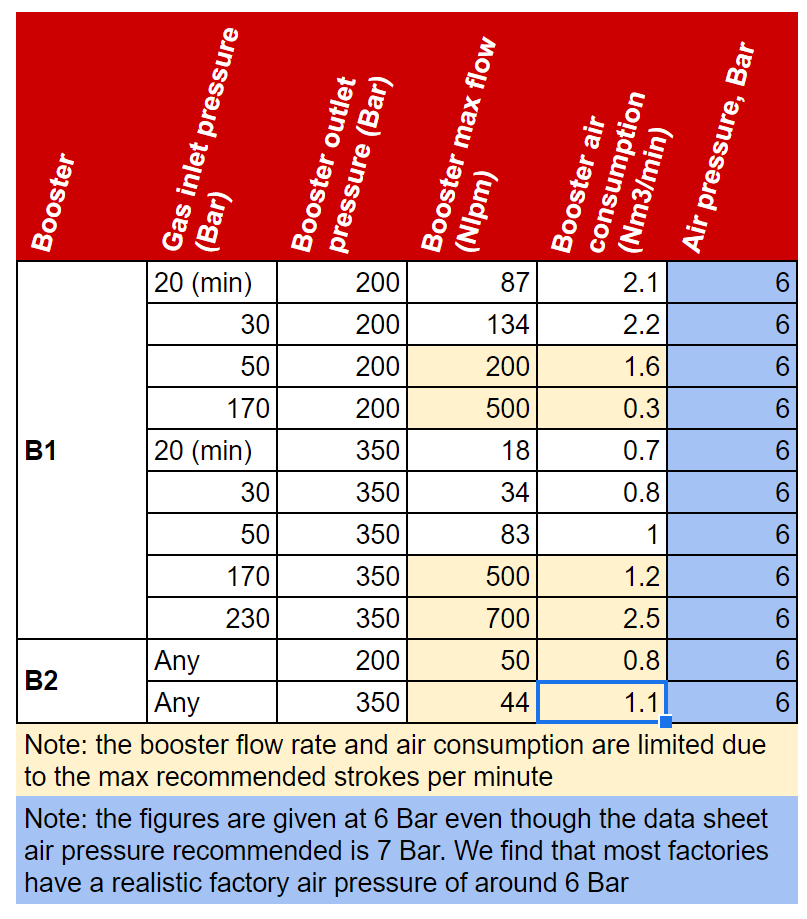

RM350 Gas and air consumption

In a gas injection moulding process, there can be a wide range of gas consumption and this depends on many factors including:

The gas pressure used to pack the moulding

The cycle time

The size of the gas channel

The length and bore of the tube connecting from the gas controller to the mould.

The amount of leaks between mould plates

The amount of leakage between the gas nozzle and the part being moulded.

Whether gas blows through an overspill (which is sometimes used to help carry away heat, but which we don’t recommend)

In general, our experience is that a gas assisted moulding channel consumes between 30 and 120 Nlpm of gas.

Gas and air consumption for RM350 units.