Hydrogen Compressors For Integrators

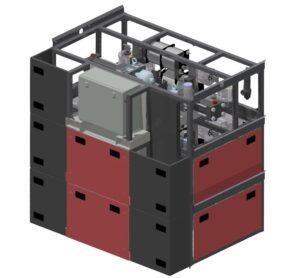

REVOLUTIONARY GAS BOOSTER SERIES – X-TOWER UP TO 900 BAR

The Maximator X-TOWER is a modular Gas Compression System, specifically designed for Hydrogen compression up to 900 bar with scalable volume flow.

The new X-TOWER technology offers an efficient way of Hydrogen compression for refuelling small fleet.

The X-TOWER solution is based on our Electro-Hydraulic Booster (EHB) Series with all the advantages of the efficiency and flexibility of Maximator’s state of the art gas compressor for hydrogen refuelling applications.

The X-TOWER is designed for integration in existing systems and covers nearly all requirements.

The interface connection is reduced to a minimum. All other modules for safe and efficient compression can be

supplied as an option if not already integrated. Web-based access to the control system offers independent

control from your mobile PC or smartphone.

With the X-Tower you are planning the future. Our solution can be adapted to new challenges by changing, adding or removing X-Modules.

Modular compressor solution for hydrogen

A standard configuration up to 900 bar consists of one MASTER-Module (control module) and up to three X-Modules (gas booster modules) – first stage module up to 270 bar, second stage module up to 540 bar and the final stage module up to 900 bar. This configuration will provide a gas outlet flow of 20 kg Hydrogen per hour. For higher outlet capacities more modules can be connected easily.

For lower inlet pressure (e.g. electrolyser) X-Modules are also available. Please get in touch with us for your detailed X-TOWER configuration.

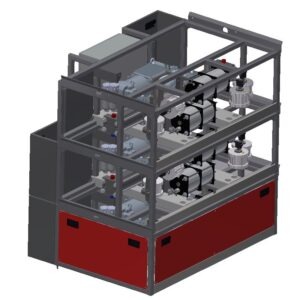

The gas compression is realized with our new EHB-Series booster technology (Electro-Hydraulic-Booster) and provides unrevealed efficiency due to their completely redesigned electrohydraulic drive concept.

For all applications the MASTER-Module is mandatory and handles safety and functional features for a maximum of three X-Modules. The X-Modules can be combined and connected depending on the application.

FLEXIBILITY

With the X-TOWER you are planning the future. Our solution can be adapted to new challenges by changing, adding or removing X-Modules.

The modular design allows many combinations of X-Modules to cover many different applications and requirements.

EFFICIENCY

With the new frequency converter controlled, completely closed hydraulic drive concept of our EHB-Series, we are providing the most efficient way to compress gases.

- Efficient hydraulic drive with less oil volume

- Flushing concept integrated

- Quiet drive technology

- Power consumption monitoring

COOLING

Intelligent and efficient new cooling concept keeps the gas temperature, the EHB and the electrical enclosures under control with minimum energy consumption.

AIR FLOW TOWER PURGE

With our revolutionary design concept of the forced ventilation and forced exhaust, we make sure, that no explosive atmosphere can occur inside the X-Tower.

INTEGRABILITY

With reduced interface connection we are proud to call: “plug & boost“.

A web-based access to the control system offers independent control with your mobile PC or smartphone. Our X-Tower Series is prepared for IoT integration to improve processes, and provide more information about the compression process than ever before. Easy integration in existing systems.

SAFETY

Purging, temperature & pressure control, gas detection, active ventilation (zone free), and safety PLC are only some of our safety features of the new X-Tower series. Safety tested and production monitored by a third party organisation.

If you are interested in a quotation for one of our X-Tower Systems, please click on the button below, or get in contact with our office

Tel 01606 636000 or email sales@maximator.co.uk