Air driven High Pressure Gas boosters

Composed under pressure…

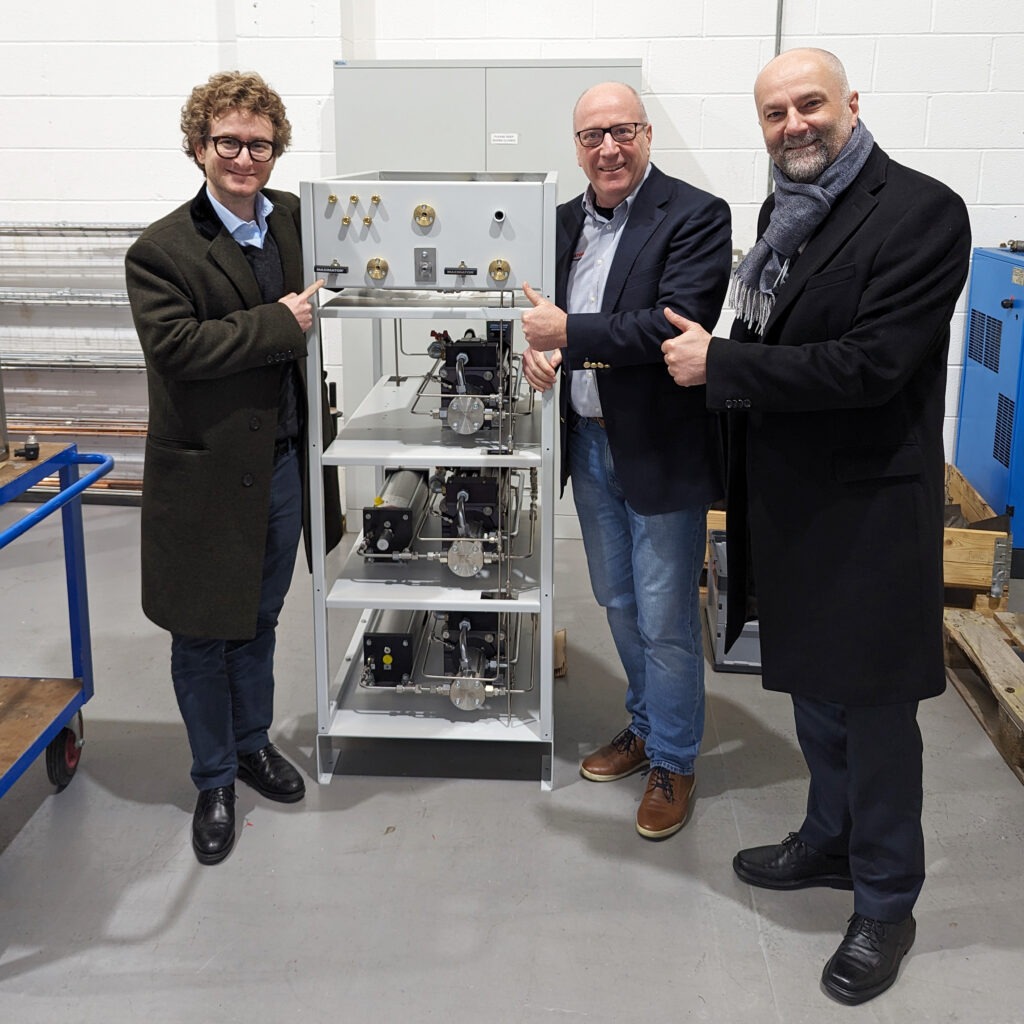

MAXIMATOR UK air driven high pressure gas boosters are suitable for the oil free compression of gases and air.

Industrial gases like Argon, Helium, Hydrogen and Nitrogen can be compressed to operating pressures of 2400 bar (36000 psi) and oxygen up to 350 bar (5075 psi), depending on the application.

Air driven gas boosters are an efficient alternative to electrically driven products for many applications and can be used in explosion-proof areas or areas without electricity supplies.

Maximator gas boosters offer the right solution for every application. As a result of the wide range of models it is possible to select the optimum booster for each application.

Maximator UK are also able to design and build bespoke solutions and sub-assemblies for any application.

For more information, visit our website HERE

Air driven High Pressure Gas boosters Read More »